|

|

Mick

McGreggor Datsun 1600 SR20det

Nervous stuff, putting the saw through a brand new turbo.

Mick became too used to the power of his 12.4 sec. ride, so he has up the

ante with a Garret GT 30bb & associated piping.

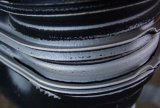

There just isn't room to connect a pipe with a good

radius onto the turbo, so we cut the end of the housing off & then welded up

a cast 90 deg. bend to match the shape & contour of the port. Notice

the corresponding "D" shape of the floor of the pipe to the turbo housing.

We also had to make a few templates to make sure we maintained the same

expanding taper in the elbow, which also gave us a better inner radius

ratio. It is important there is no mismatch so close to the turbine

wheel. At least after this the charge has a straight shot at the

intercooler. |

|

Virginia Golf

Club John Deer

We work on almost anything, & this is the slowest so far

(maybe a tie with the pedal car?). The filler kneck had corroded away

(they're only thin stamped alloy oe), so we welded on one of our billet

knecks. Definitely the best part of the cooling system now!

|

|

|

Mazbeat of Strathpine had a customer bring in his rotary oil

cooler that had been rubbed through on the bottom pipe

Weld on bottom is normal TIG. weld. We

then changed the

settings on the 'Areowave' & laid the weld down so the repair

was less noticeable when painted.

|

|

Mal Haines

Auto Electrical '93 Maxda Astina import

One of the problems with some (a few) imports

is that parts are not always available locally. A top tank to replace

this cracked one could,'t be sourced anywhere by the owner & is not listed

in any of our catalogues, Neither is an assy., so the only choice was to

fabricated one. Dearer than a tank if it was available, but at least

this tank wont crack.

Fitted straight in. |

|

RC

Greive Jaguar Jaguar XJ300

This car was involved in an accident & the

bottom of the tank was punched in. No parts are available seperately,

& a new assembly is very expensive. We fabricated a new tank to the

original oe dimentions (except for the oil cooler), turned up a sender

flange & welded it on for approx. 35% of the cost of a new radiator.

Sender flange & Inlet pipe are duplicate of oe. Much

quicker to just cut the back of the pipe off square, but we were asked to

duplicate the plastic tank, & this is a Jag.

It may be easy to manufacture in plastic, but it takes

some time in alloy. At least I know what will last the longest!

|

|

Jason May brought this broken HKS blow off valve that came in

on one of his front cuts. We welded abit of scrap on first to get our

settings right & also the correct filler rod.

Welded the flange on to the body & now we have too face it off. We

had to keep the diaphragm wrapped in wet rags or it would've melted.

|

|

|

Unfortunately I didn't take a pic. of this Supra intercooler before we

started, but this is how it finished up with both pipes being reworked for

an easy fit into a Pulsar ET turbo. Making for a cheap efficient unit,

and easy for the customer to plumb himself.

|

|

|

Strathpine Toyota had a customer with a leaking GT4 intercooler.

With the size of the split I bet there was

"buggerall" boost in the engine. We have to Hydrogen Braze this type of core

as they are oven fused together in the Denso factory with a lower temp

bonding agent. If we TIG. weld the seam, usually there is a tiny pin hole

leak at the end of the weld because of the higher TIG. welding temperature. |

|

|

Richard Galley dropped in this evo 3 intercooler of his Mit. Gallant rally

car damaged in a minor off. We straightened the damaged fins & then TIG.

welded the two damaged tubes, giving a 100% sound repair. The 'Areowave' was

set to give a high temp surface weld without too much penetration,so that

the fine internal tube fining is not melted. If this happens, they ball up

on the end of the fin & have a slight chance of breaking off. If the ball of

alloy worked it's way down the tube, next stops in the engine!

We also had to weld a pipe onto this end of the tank & pull it back into

shape. It had been punched in & the bracket torn off. We cut the pipe off,

cleaned up the area, straightened the bracket & welded it back on. Pressure

tested to 30 psi. & given back to a relieved owner - for a small fee

offcourse. |

|

|

|

|

|

|

A VW Golf oil cooler-filter adapter unit after it had

one hell of a front ender, punching the filter back into the cooler

body

We turned up a new

mount pad & welded it on. It then had to be machined flat to fix a

small distortion We tested the unit for oil-water leaks. |

|

|

had to have his plenum ends swapped. He was fitting a 4AEG from a

front wheel drive into his KE70 Corolla, which is Rear wheel drive.

This had the throttle body hitting the firewall. It was easier

for us to cut the ends off & throw them as they are not symetrical & so did

not match up at all. Pic. shows the old ends laying in the

runners.

We machined new ends

with identical internal cavities & dimensions & welded them on.

Finished article.

Almost looks factory. |

|

|

Mick McGregors SR20DET throttle body was pointing the wrong way & too

close to mate to the intercooler pipe properly. We had to cut the front off

the plenum on an angle & then machine a thick plate & weld it on |

|

|

This intercooler was damaged when a screw driver slipped, while they

were working on the engine. They thought they would be up for another second

hand unit (they had heard about glue repairs on radiators & didn't want

that) so were really relieved when I said it was no trouble to repair this

properly.

Straight after welding

If the fins weren't

damaged so much, the repair would've been allot better.

|

|